Complete Expertise Of COGD, H2 & N2 Plants

We Are Leading Experts Of O&M Of Gas Purification Plants & Systems!

Inline with the latest trends in the process industry, GAPSPL manages the day-to-day operation and maintenance activities incorporating the highest levels of involvement and commitment to the customer's plant. We work as a team (mechanical, electrical & instrumentation engineers and technicians) to operate and maintain the process plants engineered and built at customer's location. All core services of operations support, technical expertise and solutions, local/remote monitoring & diagonostics, complete maintenance planning & execution, and inventory management are seamlessly integrated into the routine operations on a daily basis. This is our most comprehensive and complex approach to service, keeping in mind the reliability and availability of the plant.

We are the only service provider for Desulfurization of Coke Oven gas & generation of Hydrogen from it. We are also into the processing & purification of Nitrogen gas by Nitrogen purification plants and waste incineratios of Incinerator plant.

Our technical experience in this field is more than 23 years. Our people are involved in this field since 1999 at CRM utility, TATA Steel Ltd. with 100% customer satisfaction compliance and assurance of accident free jobs.

We also provide technical & ECC services across the globe for different type of gas plant, ensuring smooth & easy operation for customers, with happy commissioning experience.

Our key resposibilities

- Providing of technical expertise of concern plant

- Complete plant operation and maintenance

- Spare management (emergency, shutdown, breakdown)

- Optimization of inventory

- Predictive, Preventive and break down maintenance

- Complete plant safety as well as workers safety

- 24x7 operations through field and control room operators

- Work permit management

- Process safety management & TPM across the work area

- Planned maintenance during major shutdowns

- Manning the DCS or PLC panels and Utility SCADA

- Management of consumables and dessicants

Our Team Strength

We have a dedicated and driven team of Engineers, Diploma Engineers and Supervisor along with Skilled, Semi-skilled and unskilled work force. We believe in Integrity, Commitment, Passion, Safety and well-being of our employees and take utmost care for all our jobs.

Our team also takes complete responsibility during major shutdowns with necessary pre-planning to ensure that all timelines are adhered and necessary maintenance activities are completed. We also help in up-gradation/ revamping services to enhance output of process plants, during these annual shutdowns.

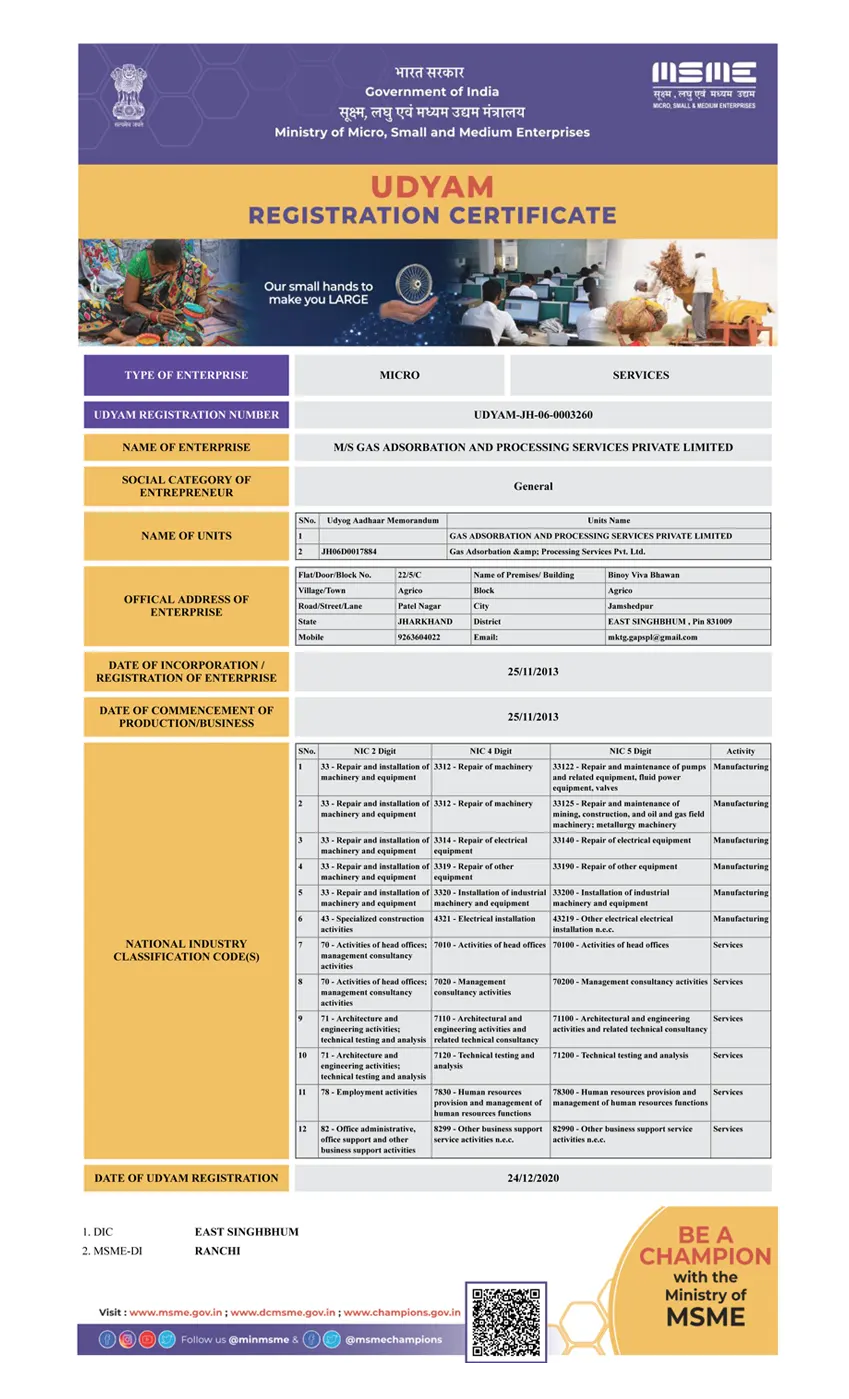

Awards & Accreditation